Microchips are hot.

The tiny bits of silicon are integral to 21st-century life because they power the smartphones we rely on, the cars we drive and the advanced weaponry that is the backbone of national security. They’re so important that the disruption of the microchip supply chain during the pandemic became an urgent national security issue.

Also, microchips are literally hot.

Those tiny chips have mighty computing power, which builds up heat around the microchip. From the beginning, in the 1950s, manufacturers designed packaging — the materials around the chips — to mitigate heat, provide protection and enable electrical current to flow.

Over the decades, as the chips became more powerful, the packaging became more sophisticated.

Now, “advanced packaging” is a critical part of the design and manufacture of chips, not only to protect them from the heat generated by ever-increasing power but also as a way to actually improve their performance — critical as the strategy of adding more transistors on ever smaller chips, the practice that has driven the industry since the 1960s, reaches both its financial and physical limits.

The newest generation of advanced packaging is integrated with the chips during the manufacturing process to make them work faster and even combine different kinds of chips onto one wafer for super advanced capabilities like artificial intelligence.

It’s as if you had a glove that not only protected your hand but also made it stronger.

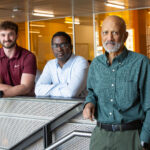

Arizona State University is poised to be a major player in this next breakthrough in microchip technology. The university is one of the few in the country that is teaching advanced packaging to its students, creating the skilled workforce that’s desperately needed by the semiconductor industry. A key asset in doing that is ASU’s partnerships with industry leaders to research the next innovations as well as create a cutting-edge production line.

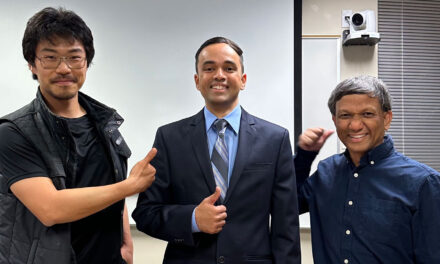

ASU has launched a ground-breaking collaboration with Deca Technologies, a Tempe, Arizona-based provider of advanced packaging technology. ASU and Deca will create North America’s first fan-out wafer-level packaging research and development center. The new Center for Advanced Wafer-Level Packaging Applications and Development will expand domestic semiconductor manufacturing and drive advancements in artificial intelligence, machine learning, automotive electronics and high-performance computing.

In addition, ASU recently entered into a partnership with NXP Semiconductors focused on advanced packaging. Fueled by the support of the Arizona Commerce Authority, ASU received $17.5 million to expand research, development and workforce training.

It’s all part of a strategy launched several years ago by ASU to become a leader in the field of advanced packaging, according to Zachary Holman, a professor in the School of Electrical, Computer and Energy Engineering at ASU.

“ASU’s competitive advantage in advanced packaging stems from our scale, the innovativeness of our faculty and our partnerships, which extend both locally with companies like Deca Technologies, NXP and others, and farther afield,” he said.

“Advanced packaging will allow the semiconductor industry to keep growing, even though shrinking transistors is no longer the path forward. And here in Arizona we have an excellent advanced packaging industry, and it’s growing.”