Local Motors, ASU partner on high-tech materials R&D for 3D-printed car

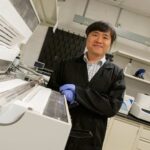

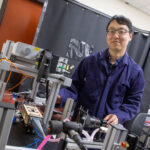

Above: The Local Motors-ASU team of student and faculty researchers will be focused on designing, simulating and fabricating a set of test structures and test systems to increase the inter-laminar strength of 3D-printed automotive parts. Keng Hsu, assistant professor of manufacturing engineering, is mentoring students working on the Local Motors eProject. Photo courtesy of Local Motors

Automotive education partnership part of ASU’s Polytechnic eProjects program

Local Motors and Arizona State University have formed a new partnership to advance materials research into 3D-printed automotive parts, which will be used on the world’s first 3D-printed cars.

Local Motors has joined the ASU Polytechnic eProjects program, which connects students and faculty in ASU’s Ira A. Fulton Schools of Engineering with cutting-edge technology companies.

Students were introduced to the eProject Capstone program partners at the 2015 Polytechnic School eProject Forum in late August. The event connected industry partners and students for the two-semester project development process.

Each eProject involves three to six students, who work together as an interdisciplinary team. At the end of their second semester the projects are revealed at the Innovation Showcase, a public event that routinely draws close to 1,000 people from industry and the community.

The photo shows a closer look at the 3D-printed plastic panel. The car is built in layers squirted from the nozzles of a massive printer. Photo courtesy of Local Motors

“The materials research and testing we are conducting with ASU will help us bring to market the world’s first 3D-printed car,” said John B. Rogers Jr., CEO and co-founder of Local Motors. “Our goal is to create vehicles that are safer than any on the road today, and this partnership with a world-class university right in our own backyard will help us do exactly that.”

The Local Motors-ASU team of student and faculty researchers will be focused on designing, simulating and fabricating a set of test structures and test systems to increase the inter-laminar strength of 3D-printed automotive parts.

Keng Hsu, assistant professor of manufacturing engineering, is mentoring students working on the Local Motors eProject.

Local Motors debuted the world’s first 3D-printed cars last year. Designs for a new vehicle are in progress in parallel with materials development and testing. The first models are expected to hit roads in 2017.

“We are happy that Local Motors is partnering with ASU, and that they see our students and faculty as valuable assets to help advance their 3D-printed vehicles,” said Ann McKenna, director of the Polytechnic School. “The exemplary team-based, industry-relevant learning experiences that these types of projects provide is what attracts students to the Polytechnic School and keeps them motivated and engaged throughout their academic years.”

This new partnership brings ASU into the Local Motors LOCO Program. Short for Local Motors Co-Created, the LOCO University Vehicle Program provides university students and faculty with the projects, vehicles and co-creation platform needed to quickly develop the next generation of vehicle technology.

Malcolm Green, associate director for corporate engagement, leads ASU’s overall partnership with Local Motors and arranged the donation of the 3D-printed LOCO vehicle to the Polytechnic School.

John M. Parsey Jr., director of eProjects at ASU’s Polytechnic School, is establishing a “3D Car” student club to continue the development activities on the LOCO vehicle.

“This is an exciting and innovative set of projects for our students to be working on, and it will give them the opportunity to learn at the cutting-edge of engineering and put their creative minds to work on a real-world challenge,” Parsey said. “It fits perfectly within our eProjects program, which gives students outstanding workplace experience while they are at the university.”

The ASU teams will have access to Local Motors’ Chandler operations and its large-scale 3D-printer in Tempe. The printer, and others like it, will be used to create the next generation of the Local Motors 3D-printed car.

By Sharon Keeler